If you’re in the market for pipe fittings, 당신은 약관을 접했을 수도 있습니다 “관절을 밀어” 그리고 “기계식 조인트 피팅.” 두 가지 유형의 피팅 모두 파이프를 연결하는 데 사용되지만, 그들 사이에는 몇 가지 중요한 차이점이 있습니다..

소개

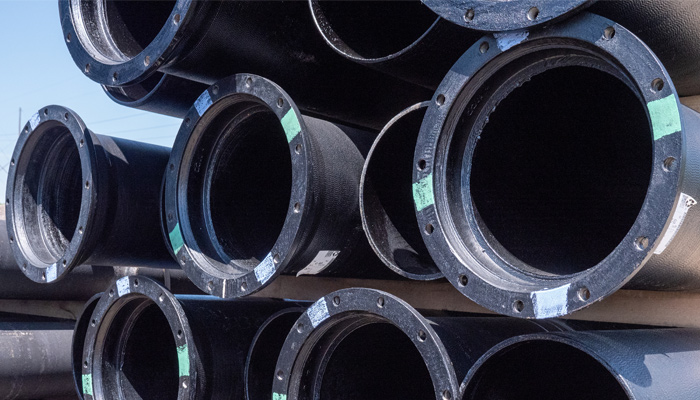

A push on joint is a type of fitting that is designed to be easily pushed onto a pipe. It works by using a specialized rubber or plastic material that is flexible enough to compress and fit snugly onto the pipe.

Once the fitting is in place, it is held securely by the pipe’s pressure. Push on joints are typically used in low-pressure applications, such as in residential plumbing systems.

Difference Between These Two Products

기계식 조인트 피팅, 반면에, are designed for use in high-pressure applications, such as in industrial settings. These fittings are made of metal and use a specialized mechanism to connect pipes. The mechanism is typically a cam lock or a threaded connection that is designed to create a secure, 누출 방지 조인트.

One of the main advantages of mechanical joint fittings is their ability to withstand high levels of pressure. They are also more durable than push on joints and can withstand the wear and tear of repeated use.

추가적으로, mechanical joint fittings can be easily disassembled and reassembled, making them a great choice for applications where maintenance is a concern.

하지만, there are also some downsides to mechanical joint fittings. They can be more difficult to install than push on joints, and they often require specialized tools and expertise. 추가적으로, mechanical joint fittings can be more expensive than push on joints.

So, when should you use a push on joint and when should you use a mechanical joint fitting? If you’re working with low-pressure applications, such as residential plumbing, a push on joint may be the best choice.

They are easy to install, require no specialized tools, and are generally less expensive. 하지만, if you’re working with high-pressure applications, such as in industrial settings, a mechanical joint fitting is the better choice. They are more durable, can withstand high levels of pressure, and can be easily disassembled and reassembled.

결론

요약하자면, the main difference between a push on joint and a mechanical joint fitting is the level of pressure they can withstand. Push on joints are designed for low-pressure applications, while mechanical joint fittings are designed for high-pressure applications.

추가적으로, mechanical joint fittings are more durable and can be easily disassembled and reassembled, but they are also more difficult to install and may require specialized tools and expertise.