리지드 클램프 커플링은 세 가지 범주로 분류됩니다., 각각 고유한 특성과 장점이 있습니다.. 이 에세이는 이러한 각 범주를 심층적으로 다룰 것입니다., 그 특성과 응용을 강조.

Tapered Clamp Couplings

The most frequent type of rigid clamp coupling is a tapered clamp coupling. They are made up of a tapered sleeve and a clamping nut that work together to bind two shafts or tubes.

The tapered sleeve is intended to fit over the shafts or tubes, while the clamping nut compresses the sleeve and creates a tight fit. Tapered clamp couplings come in a variety of sizes to accommodate various shaft or tube diameters.

Straight Clamp Couplings

Straight clamp couplings are similar to tapered clamp couplings in appearance, but they lack a tapered sleeve. Instead, they secure the connection using a straight sleeve and a clamping nut.

Straight clamp couplings are frequently utilized in situations requiring a high level of torque or thrust because they can withstand larger loads than tapered clamp couplings.

Elastomeric Clamp Couplings

Elastomeric clamp couplings are the most adaptable stiff clamp coupling kind. They are constructed up of an elastomeric sleeve, such as rubber or silicone, and a clamping nut.

The elastomeric sleeve connects the two shafts or tubes flexibly, allowing for misalignment and vibration attenuation. Elastomeric clamp couplings are appropriate for applications where flexibility and stress absorption are required.

결론

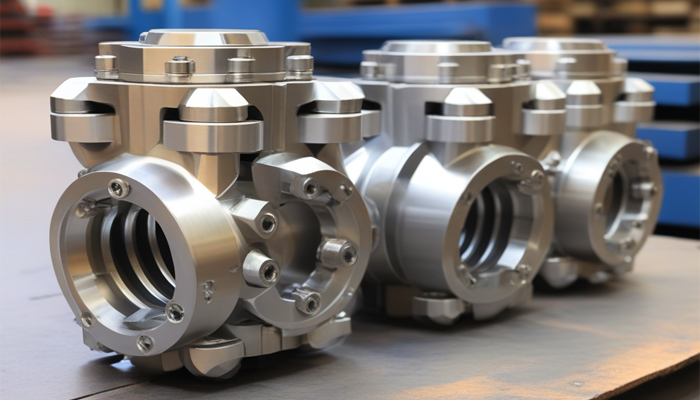

Rigid clamp couplings are a necessary component in many industrial applications because they provide a secure and robust connection between two shafts or tubes. 리지드 클램프 커플링은 세 가지 범주로 분류됩니다., 각각 고유한 특성과 장점이 있습니다..

Engineers may select the proper coupling for their unique application by understanding the distinctions between these types. This ensures optimal performance and dependability.