Elbows are a fundamental component in plumbing and HVAC systems, used to redirect fluid flow and connect pipes. In this article, we will explore the key differences between long radius and short radius elbows, and when to use each type.

Short Radius Grooved Elbow

A short radius grooved elbow is a type of elbow that has a shorter radius than a long radius elbow. The radius is the distance from the center of the elbow to the end of the pipe.

Short radius elbows are typically used in smaller diameter pipes and are designed to bend at a smaller angle than long radius elbows. They are commonly used in residential plumbing and HVAC systems.

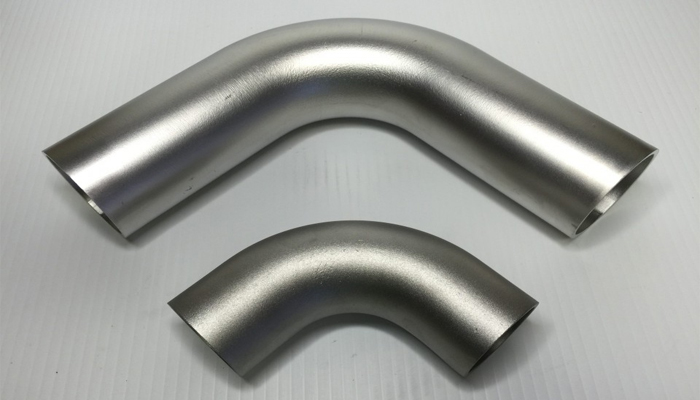

Long Radius Grooved Elbow

A long radius grooved elbow, on the other hand, has a longer radius than a short radius elbow. Long radius elbows are typically used in larger diameter pipes.

And are designed to bend at a larger angle than short radius elbows. They are commonly used in commercial and industrial plumbing and HVAC systems.

Key Differences Between Long Radius and Short Radius Elbows

The key differences between long radius and short radius elbows lie in their design and functionality. Here are some of the main differences:

- Radius: As mentioned earlier, the radius of a long radius elbow is longer than that of a short radius elbow. This means that long radius elbows can accommodate larger diameter pipes and can bend at a greater angle than short radius elbows.

- Flow Direction: The flow direction of fluid through the elbow is also affected by the radius. In general, long radius elbows allow for a greater flow rate than short radius elbows, as they have a wider opening and can accommodate larger diameter pipes.

- Pressure Drop: The pressure drop across a long radius elbow is typically higher than that of a short radius elbow, as the longer radius creates more friction within the elbow. This means that long radius elbows are not suitable for applications where low pressure drop is critical.

- Material: Long radius and short radius elbows are typically made from the same materials, such as copper, PVC, or CPVC. However, the specific materials and construction techniques used may vary depending on the intended application and the desired level of durability.

When to Use Each Type of Elbow

So, when do you use a long radius elbow versus a short radius elbow? Here are some general guidelines:

- Residential Applications: For residential plumbing and HVAC systems, short radius elbows are usually the best choice. They are easier to install and can accommodate smaller diameter pipes.

- Commercial and Industrial Applications: For commercial and industrial applications, long radius elbows are often the better choice. They can accommodate larger diameter pipes and can handle higher flow rates and pressure drops.

- Low Pressure Drop Applications: If the low pressure drop is critical, such as in applications where water conservation is important, a short radius elbow may be the better choice.

- High Pressure Drop Applications: If the high pressure drop is acceptable, such as in applications where the primary concern is flow rate, a long radius elbow may be the better choice.

Conclusion

In conclusion, while both long radius and short radius elbows serve the same purpose, they differ in terms of their design and functionality. The choice between the two depends on the specific application, the desired level of durability, and the flow rate and pressure drop requirements.

By understanding the key differences between these two types of elbows, you can make informed decisions when selecting the right elbow for your next plumbing or HVAC project.