Whether in plumbing, HVAC, or industrial applications, flexible grooved couplings ensure efficient fluid flow and simplify maintenance. Learn about their construction, benefits, and industry applications to make informed decisions for your specific piping needs.

Introduction: What is a Flexible Grooved Coupling?

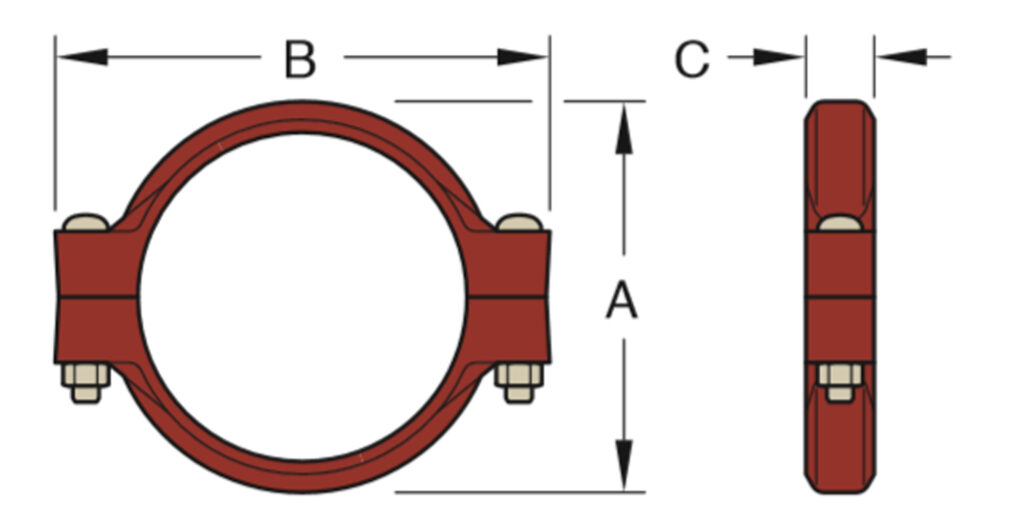

A flexible grooved coupling is a mechanical joint to connects and secures pipes in a piping system. It consists of two housings with grooves and a flexible gasket that fits between them. This innovative design allows for easy assembly and disassembly while accommodating movement and vibration.

Construction and Design of Flexible Grooved Couplings

The coupling consists of two halves with internal grooves that match the pipe’s external grooves. A flexible gasket made of rubber or elastomer material provides a watertight seal and allows for movement.

Key Features and Benefits of Flexible Grooved Couplings

- Flexibility: The flexible design of grooved couplings allows for axial, angular, and radial movement, accommodating thermal expansion, ground settlement, and vibration.

- Easy Installation: The grooved coupling’s simple design enables quick and hassle-free installation, reducing labor time and costs.

- Reliable Performance: The secure connection provided by grooved couplings ensures leak-free operation and minimizes the risk of pipe disconnection or failure.

- Versatility: Flexible grooved couplings are suitable for a wide range of applications, including plumbing, HVAC, fire protection systems, and industrial processes.

Applications of Flexible Grooved Couplings

- Plumbing Systems: Flexible grooved couplings are popular in plumbing installations for connecting water supply lines, drainage systems, and sprinkler pipes.

- HVAC Systems: These couplings facilitate the connection of HVAC pipes, allowing for efficient heating, cooling, and air distribution.

- Fire Protection Systems: Flexible grooved couplings play a vital role in fire suppression systems, ensuring reliable and quick water delivery to sprinklers and hydrants.

- Industrial Applications: In industrial settings, grooved couplings are employed in process piping.

Example: Flexible Grooved Couplings in Plumbing Systems

In plumbing systems, flexible grooved couplings offer significant advantages. For instance, during renovations or repairs, these couplings simplify the process by allowing easy disconnection and reconnection of pipes. Additionally, they absorb vibrations and movements, minimizing the risk of pipe damage due to ground settlement or shifting.

Conclusion: Enhance Piping Efficiency with Flexible Grooved Couplings

Flexible grooved couplings provide a reliable and efficient solution for connecting pipes in various applications. Their flexibility, ease of installation, and reliable performance make them a preferred choice in plumbing, HVAC, fire protection, and industrial systems.

By incorporating flexible grooved couplings into your piping infrastructure, you can streamline operations, reduce maintenance costs, and ensure long-term performance.

Make the smart choice and harness the benefits of flexible grooved couplings to optimize your piping systems. Enjoy the convenience, versatility, and efficiency they offer for a wide range of applications. Upgrade your piping infrastructure with these innovative connectors and experience enhanced performance and peace of mind.