Grooved couplings and fittings are a common term used in various industries, including plumbing, HVAC, and industrial applications. They offer several advantages, including ease of installation, security, corrosion resistance, and versatility.

The word “grooved joints” is frequently used in the plumbing, HVAC, and industrial applications industries. However, what is a grooved joint exactly?

We will give a thorough explanation of grooved couplings and fittings in this post, along with information on their types, uses, and advantages.

The Advantages of Integrated Fittings and Couplings

Compared to traditional connections, grooved fittings have several advantages. They offer a secure connection and are simple to set up.

and have a resistance to wear and corrosion. Additionally adaptable, grooved couplings and fittings work with a range of pipe materials, such as steel, PVC, and CPVC.

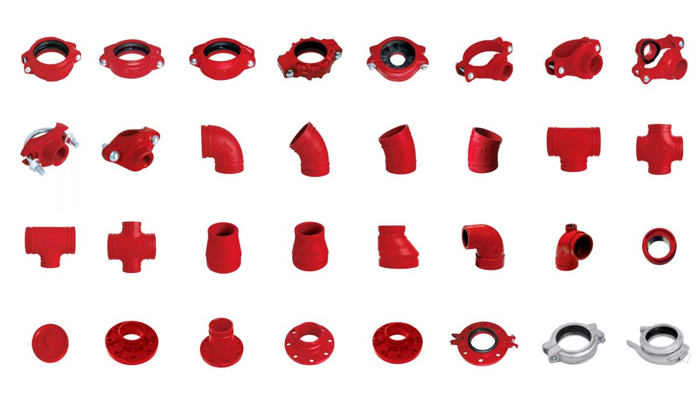

Variety of Grooved Fittings and Couplings

Grooved couplings and fittings come in several varieties, such as:

- Slip-on couplings: A retaining ring is used to secure these couplings once they are slipped over the pipe.

- Belleville-style couplings: A compressive force is used in these couplings to establish a stable connection.

- Compression-type couplings: A compression nut and washer are used to fasten these couplings.

- Threaded couplings: A nut is used to secure these couplings once they are fitted onto the pipe.

Uses for Grooved Fittings and Couplings

Applications for grooved couplings and fittings are numerous and include:

- Plumbing: To connect pipes and fittings in both residential and commercial plumbing, grooved couplings and fittings are utilized.

- HVAC: Pipes and fittings in heating, ventilation, and air conditioning systems are connected by grooved couplings and fittings.

- Applications in industry: To join pipes and fittings in the production of chemicals, foods, and pharmaceuticals, grooved couplings and fittings are utilized in industrial settings.

In summary

In summary, grooved couplings and fittings offer a dependable connection option for a range of industrial applications. They provide versatility, security, resistance to corrosion, and ease of installation.

Your next project will profit from an informed choice of connection method if you are aware of the types, advantages, and uses of grooved couplings and fittings.