Grooved pipe fittings are an important component of today’s plumbing and heating systems. What are grooved pipe fittings and how do they function? In this post, we will look at the history, kinds, and applications of fittings for pipes.

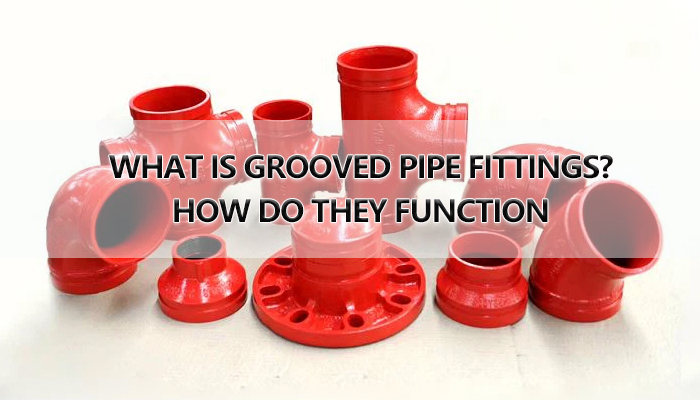

What is Grooved Pipe Fittings

Pipe fittings with grooves have been around for generations. Fittings were first seen in ancient Egypt when they were used to join wooden pipes for irrigation systems.

The Romans employed fittings in their plumbing systems as well, and the technique evolved throughout the years. These pipe fittings were frequently utilized in plumbing and heating systems in the United States during the nineteenth century.

Types

Grooved pipe fittings come in a variety of styles, each with its own set of qualities and applications. The following are some of the most prevalent varieties of fittings:

- Couplings: These are used to unite two pipes and offer a secure, leak-proof connection.

- Elbows: These are used to change the direction of a pipe and come in a variety of angles.

- Tees: These are used to join three pipes together and come in a variety of sizes.

- Flanges are used to connect a pipe to a fitting or another pipe and come in a variety of sizes.

- Unions: These are used to link two pipes and allow them to be easily disconnected.

Grooved Pipe Fitting Applications

These pipe fittings are used extensively in a variety of sectors, including:

- These fittings are popular in plumbing to connect water supply, drain, and gas lines.

- HVAC: Heating, ventilation, and air conditioning systems are all connected using pipe connections.

- Industrial: Fittings are used to join pipes in industrial environments for various functions such as chemical processing, oil refining, and power production.

- Fire Protection: The fittings connect pipes for fire sprinkler systems and fire hydrants in fire protection systems.

Advantages

Grooved pipe fittings have various advantages, including:

- Pipe fittings offer a secure, leak-proof connection that can tolerate high pressure and temperature.

- These fittings are composed of high-quality materials that are resistant to corrosion wear and strain.

- Flexibility: It comes in a variety of diameters and angles, making it simple to install and adapt to diverse pipe configurations.

- These pipe fittings are inexpensive and can save time and money on installation and maintenance.

Pipe Fitting Installation

Installing this pipe fitting necessitates the use of specialized tools and procedures. The following are the fundamental steps for installing fittings:

- Cleaning and preparing the pipe is required before installing the fitting.

- trimmed the pipe: To fit the fitting, the pipe must be trimmed to the necessary length.

- Groove the pipe: To suit the fitting, the pipe must be grooved.

- Fitting installation: The fitting is screwed onto the pipe.

- Secure the fitting: A coupling or other fastening mechanism is used to secure the fitting to the pipe.

Grooved Pipe Fittings Maintenance

Grooved pipe fittings must be serviced regularly to ensure optimal operation. Here are some pointers for keeping the pipe fittings in good condition:

- Inspect the fittings regularly: Regular inspections can assist in identifying possible concerns before they become severe difficulties.

- Clean the fittings: Dirt and debris can accumulate on fittings, thus they must be cleaned regularly.

- Lubricate the fittings: Lubricating the fittings helps to reduce friction and corrosion.