Mechanical joint fittings are an essential component in many industrial and commercial applications. In this article, we will explore the different types of these joint fittings, their features, and applications, to help you make an informed decision.

Choosing the Right Mechanical Joint Fitting

When selecting a mechanical joint fitting, it is important to consider the following factors:

- Application

Mechanical joint fittings are used in a wide range of applications, including oil and gas, water treatment, chemical processing, and HVAC systems. Each application has unique requirements, so it is important to choose a fitting that is designed for your specific needs. - Pipe Material

The type of pipe material used will also play a significant role in determining the right fitting. Fittings are available for use with a variety of materials, including carbon steel, stainless steel, and PVC. - Pressure and Temperature Ratings

The pressure and temperature ratings of the fitting must match the requirements of the application. Look for fittings that are rated for the appropriate pressure and temperature range for your specific needs. - Ease of Installation

The ease of installation is an important consideration when choosing a joint fitting. Look for fittings that are easy to install and require minimal effort to maintain.

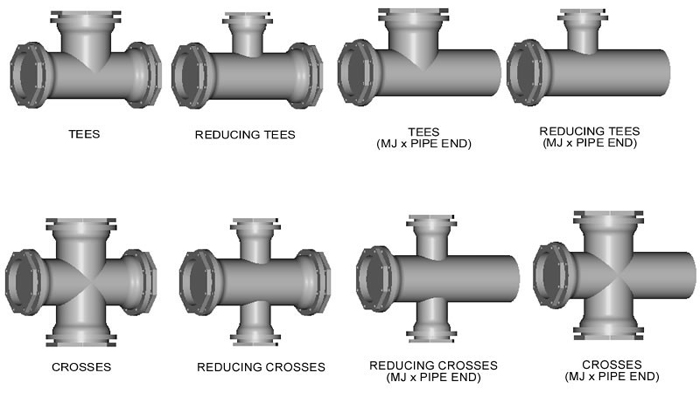

Types

There are several types of mechanical joint fittings available, each with its unique features and applications. Some of the most common types include:

- Compression Fittings

Compression fittings are the most commonly used type of fitting. They work by compressing the pipe and fitting it together, creating a secure connection. - Slip-On Fittings

Slip-on fittings are similar to compression fittings, but they do not require the pipe to be compressed. Instead, the fitting slides over the pipe and is held in place by a nut. - Threaded Fittings

Threaded fittings are used in applications where a more permanent connection is required. They are threaded onto the pipe and secured with a nut. - Sockett-Style Fittings

Sockett-style fittings are used in high-pressure applications and feature a socket that fits over the pipe. They are secured with a nut and are highly durable.

Applications of Mechanical Joint Fittings

Mechanical joint fittings are used in a wide range of applications, including:

- Oil and Gas

These fittings are used in oil and gas applications to connect pipes and fittings securely and durably. - Water Treatment

These fittings are used in water treatment plants to connect pipes and fittings in a corrosive environment. - Chemical Processing

The joint fittings are used in chemical processing plants to connect pipes and fittings in a highly corrosive environment. - HVAC Systems

Mechanical joint fittings are used in HVAC systems to connect pipes and fittings in a variety of applications, including heating, cooling, and ventilation.

Conclusion

Choosing the right fitting for your specific needs can be challenging, but by considering the factors outlined above, you can make an informed decision.

With so many different types of mechanical joint fittings available, it is important to select the one that best meets your needs. By doing so, you can ensure a secure and durable connection between your pipes and fittings, and improve the overall performance of your system.