While threaded fittings are stronger and more leak-resistant, grooved fittings are simpler to install and maintain. Selecting the best type for a given project can be made easier by being aware of the benefits and distinctions between each type.

Difference between Grooved and Threaded Fittings

There are two primary types of pipe fittings: threaded and grooved. Although they are both intended to join pipes and enable fluid movement, there are several significant distinctions between them. This article will examine the distinctions between threaded and grooved fittings, as well as their benefits and uses.

Curved Brackets

Grooved pipe fittings are made with a channel or groove running the length of the fitting. The pipe is inserted into this groove and fastened in position using a gland or coupling.

The pipe can rotate against a smooth, continuous surface in the groove, making installation and maintenance simple. Plumbing, HVAC, and fire sprinkler systems are three prominent applications for grooved fittings.

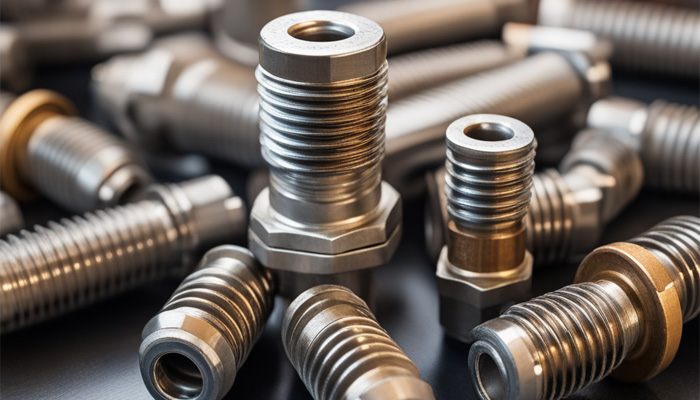

Threaded Fittings

Threaded fittings, on the other hand, have a threaded design that is used to connect pipes. The threads are cut into the fitting, and the pipe is screwed into the fitting to create a secure connection. Threaded fittings are commonly used in water supply systems, gas lines, and sewage systems.

Advantages of Grooved Pipe Fittings

Grooved fittings have several advantages over threaded fittings. One of the main benefits is that they are easier to install and maintain. The groove provides a smooth surface for the pipe to rotate against, making it easier to connect and disconnect the pipe.

Additionally, grooved fittings are less likely to damage the pipe, as the groove does not cut into the pipe like threads do. This makes grooved fittings a better option for systems that require frequent maintenance or repairs.

Advantages of Threaded Fittings

Threaded fittings also have their advantages. They are generally stronger than grooved fittings, as the threads provide a more secure connection.

Threaded fittings are also more resistant to leaks, as the threads create a tighter seal. This makes threaded fittings a better option for high-pressure systems and applications where leaks could be catastrophic.

Applications of Grooved Pipe Fittings

Grooved fittings are commonly used in fire sprinkler systems, HVAC systems, and plumbing applications. They are also used in chemical processing, oil and gas production, and water treatment plants.

Grooved fittings are a better option in these applications because they are easier to maintain and repair, and they are less likely to damage the pipe.

Applications of Threaded Fittings

Threaded fittings are commonly used in water supply systems, gas lines, and sewage systems. They are also used in industrial applications.

Such as chemical processing, oil and gas production, and power generation. Threaded fittings are a better option in these applications because they are stronger and more resistant to leaks.

Conclusion

In conclusion, grooved and threaded fittings are two different types of pipe fittings that have their advantages and applications. Grooved fittings are easier to install and maintain, and they are less likely to damage the pipe.

Threaded fittings are stronger and more resistant to leaks. Understanding the differences between these two types of fittings can help you make an informed decision when selecting pipe fittings for your next project.