Mechanical Pipe Fittings

- Durability: Withstand high pressure and temperature

- Strength: Handle mechanical stress and vibrations

- Variety: Allowing for flexibility in design and installation

- Flexibility: convenient choice for maintenance and repairs

- Cost-effective: Reducing the need for frequent replacements

- Resistance to corrosion: Reducing maintenance costs

Product Description

Mechanical Pipe Fittings – Efficient and Reliable Solutions for Plumbing Systems

Mechanical pipe fittings are designed to withstand the mechanical stress and pressure of piping systems. They are typically made of metal, such as carbon steel, stainless steel, or copper, and are available in various shapes, sizes, and configurations. The most common types of mechanical pipe fittings include:

- Elbows: used to change the direction of a pipe by 90 degrees or 45 degrees.

- Tees: used to connect pipes at a 90-degree angle, with one inlet and one outlet.

- Couplings: used to connect two pipes together, often with a male and female thread.

- Unions: similar to couplings, but with a removable plug for easy disconnection.

- Flexible fittings: used to absorb vibrations and movements in piping systems.

Uses of Mechanical Pipe Fittings

Mechanical pipe fittings are used in a wide range of industries, including:

- Oil and gas: used in upstream, midstream, and downstream applications.

- Chemical processing: used to handle corrosive and hazardous chemicals.

- Water treatment: used in potable water, wastewater, and sewage treatment plants.

- HVAC: used in heating, ventilation, and air conditioning systems.

- Marine: used in shipbuilding and offshore platforms.

Benefits of Mechanical Pipe Fittings

Mechanical pipe fittings offer several benefits, including:

- Durability: able to withstand high pressure and temperature.

- Strength: can handle mechanical stress and vibrations.

- Variety: available in a range of materials, sizes, and configurations.

- Flexibility: can be easily connected and disconnected.

- Cost-effective: a reliable and long-lasting solution.

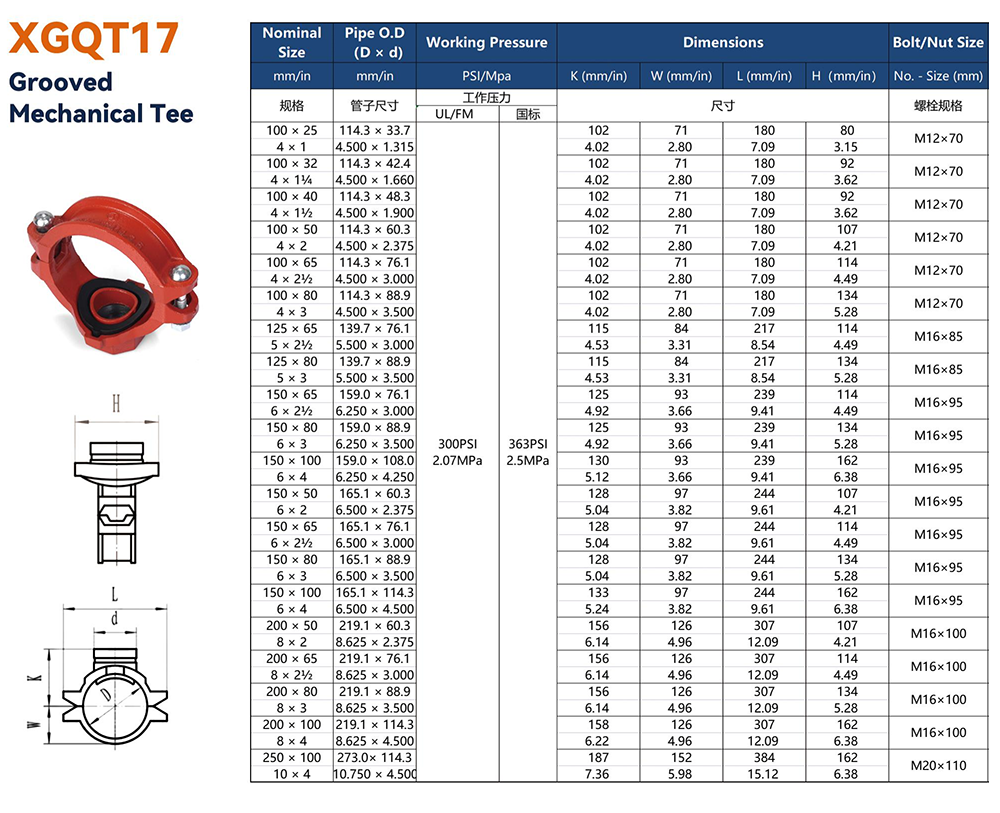

Specification

Considerations for Selecting Mechanical Pipe Fittings

When selecting mechanical pipe fittings, several factors must be considered, including:

- Pressure rating: the fitting must be able to withstand the maximum pressure of the system.

- Temperature rating: the fitting must be able to handle the operating temperature of the fluid.

- Material selection: the fitting must be made of a material compatible with the fluid being transported.

- Size and configuration: the fitting must match the size and configuration of the piping system.

- Standards and certifications: the fitting must meet industry standards and regulations.